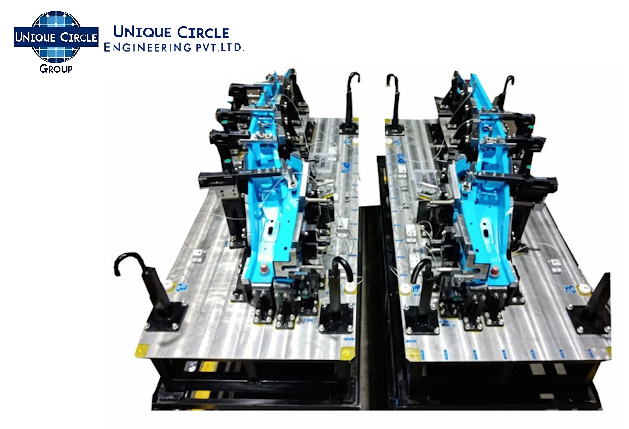

Unique Circle Engineering Pvt. Ltd is the leading BIW Assembly Fixture manufacturers in India, suppliers, and exporters in India. We produce and supply a wide range of BIW assembly Fixture that are highly specific and customizable by-their-very-designs and shapes to fit different vehicle models. All these allow the fixture to be adjusted to new shapes or variations, making these Fixtures suitable for multi-model manufacturing lines.

BIW Assembly Fixture Suppliers and Exporters in India:

As the best BIW Assembly Fixture Suppliers in India we designed fixtures for loading and carrying the metric weight and size of very large automotive body parts. The Fixtures hold very heavy components strongly and securely so that they are stable and accurately positioned during the complete assembly process. These Fixtures have been designed with precise anti-vibration mechanisms. This minimizes misalignment and keeps assembly processes precise.

Types of BIW Assembly Fixture:

We, BIW Assembly Fixture Exporters in India, offer several types of it to ensure multiple choices for the customers.

- Master Gate Fixture: These products serve as basic large elements which create vital reference points for the entire vehicle body structure. Such Fixture guarantee exact match between major body panels as well as their fundamental dimensional coordination. The assembly process uses master gates as its fundamental starting point for all following stages.

- Framing Fixture: The main structural components of vehicles are assembled through these Fixtures by joining floor pan and side panels together with roof sections. These components get properly positioned through these Fixtures before undergoing welding to create the basic body structure.

- Sub-Assembly Fixture: The purpose of these Fixtures is to combine smaller units into sub-assembly components that will ultimately become part of the main body construction. Three examples of sub-assembly Fixture consist of door frames together with hood assemblies and trunk lids.

- Checking Fixture (BIW Specific): Checking Fixtures maintain their general characteristics in BIW applications but they become large devices which validate the comprehensive body dimensions alongside critical points after welding tasks. These elements ensure that the BIW meets engineering requirements and frequently work alongside CMM systems to execute this check.

For flexible and scalable assembly solutions, pair your BIW setup with our

Modular Fixtures, designed to adapt to evolving vehicle models and production requirements.

Key Features of BIW Assembly Fixture:

As BIW Assembly Fixture suppliers and manufacturers in India, here are some features of it.

- Precision Alignment: The precise positioning of body components - chassis, doors, roof and side panels- during assembly is made possible with the assembly Fixture designed for BIW. Integrity and appropriate fit of the body structure has in fact its importance.

- Sturdy and Durable Construction: These types of Fixture are made of high strength materials like steel so they are very durable and can withstand the standard harsh conditions in the automotive assembly line. The strong construction guarantees their reliability upon repeated use during very high volume production.

- Modular Components: Many of the BIW assembly Fixture use a modular design whereby components of the Fixture can be rearranged or replaced for any specific assembly process. The fixture becomes more open-ended and cost effective for different vehicle models by this modularity.

- High Repeatability: This means that any part operates under the same orientation during the successive assembly operations. Joining of components will take place only with high accuracy during each repetition and this is very crucial for ensuring quality.

- Ergonomically Designed: Designing of such Fixture involves ergonomic aspects making it effortless for the operator to work to these Fixture as an example adjustable heights, easy-to-use clamping mechanisms and reaching components that have been made to be easy in minimizing operator fatigue during long hours.

Applications of BIW Assembly Fixture:

We are among the top BIW Assembly Fixture Manufacturers in India, below are some applications of it.

- Automotive Body Assembly: BIW Fixtures find broad applications in the assembly of automotive body components. They are used for holding, aligning, and positioning body panels, doors, roofs, and other structural components.

- Welding Operations: Assembly BIW Fixtures are used to keep parts in place while welding. The Fixture will ensure that body panels and any other components are in alignment for accurate welds.

- Spot Welding: Spot welding is most frequently used in the BIW assembly, using specialized Fixture to hold the parts in place during welding.

- Gluing and Sealing: Besides mechanical fastening, BIW assembly Fixture act as holding devices during adhesive bonding or sealing operations.

Why choose us?

Being the reputed BIW Assembly Fixture manufacturers in India, suppliers, and exporters in India, at Unique Circle Engineering Pvt. Ltd, we offer top grade assembly Fixture Solutions at reasonable rates which suitable for many automotive and welding applications. All our offered Fixture are demanded by the customers for their productivity and quality. Thus, Contact us and get the best BIW Assembly Fixture in India!