Unique Circle Engineering Pvt. Ltd is the leading Glass Checking Fixture manufacturers, suppliers, and exporters in India, designing and offering top-quality fixtures to check glass dimensions, thickness, shape, and other factors. Each of these fixtures is tested under the strict surveillance of our quality assurance team to deliver flawless and defect-free fixtures to the customers at the end.

Glass Checking Fixture Suppliers and Exporters in India

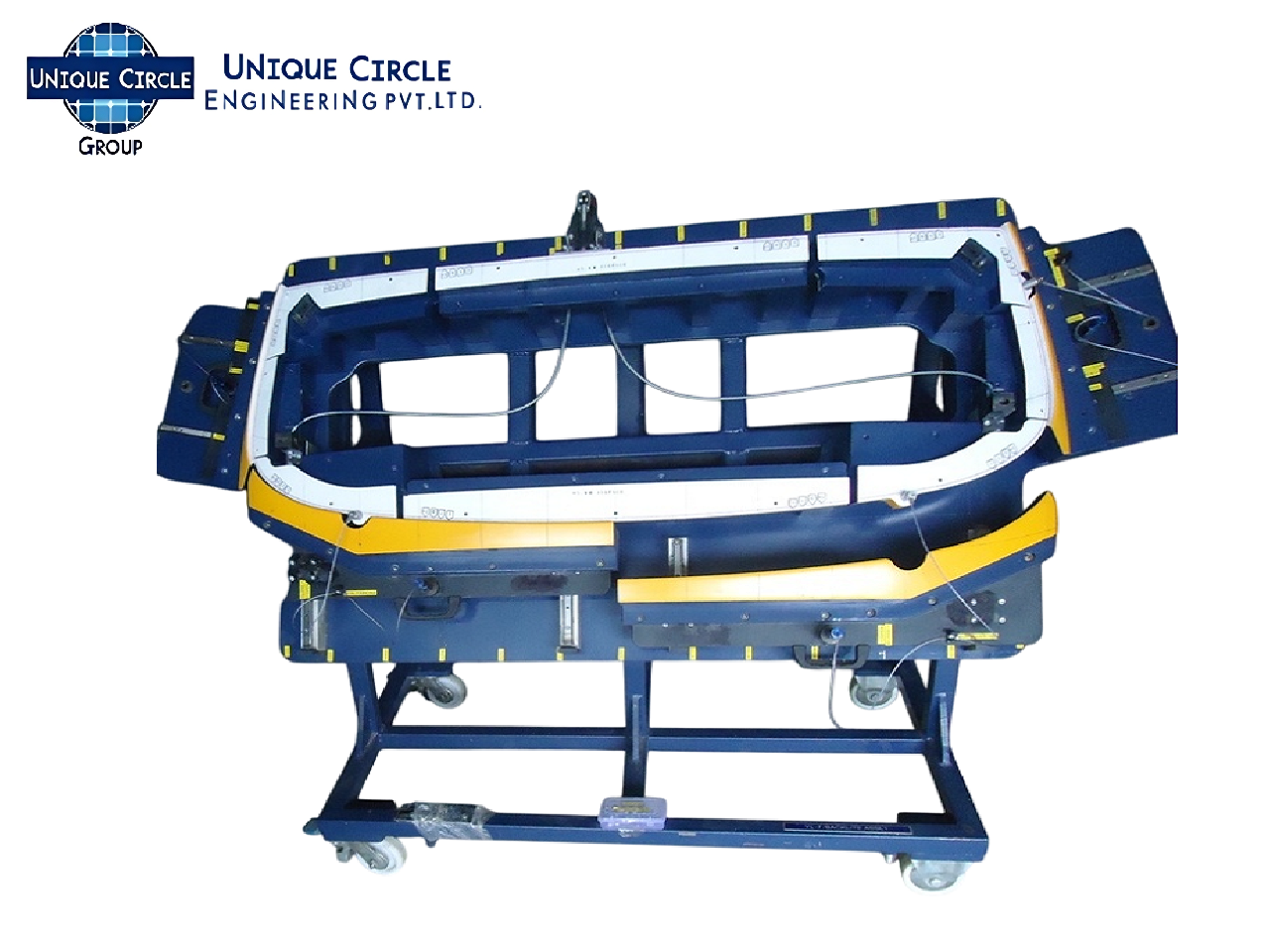

As we are a top Glass Checking Fixture manufacturers in India, these are made from very high-resistant materials such as aluminum, steel, or reinforced plastics, which withstand repeated use and last for a long time. They thus offer damage-free handling of delicate and fragile glass components. As Glass Checking Fixtures suppliers, we supply these fixtures which come with a gauge, caliper, or a digital measuring device incorporated in the fixture for checking the thickness, flatness, or curvature of the glass. This thus makes the inspection process simpler and improves its accuracy.

Types of Glass Checking Fixtures:

We, glass checking fixture suppliers in India, provide various types of them to fulfill wide requirements of different applications. Some of these types are mentioned below.

- Automotive Glass Checking Fixture: Industrial devices named fixtures exist to check the dimensions and form of automotive glass segments which include windshields along with side windows and rear windows. Through their inspection methods, the fixtures check glass components for correct placement inside the vehicle frame to match security specs and beauty standards. The fixtures handle components that require complex shaped curvature and multiple mounting attachments.

- Glass Measurement Fixture: This wider group of fixtures helps inspect glass components by measuring their thicknesses and shapes as well as their profiles on the edges. Fitting requirements are met by employing advanced measuring machinery combined with specific techniques in these fixtures.

- Precision Glass Checking Tool: These instruments serve to check glass components at high levels of accuracy while examining key dimensions plus tolerance areas. Device measurement technology including laser scanning and optical gauging makes sure glass products fulfill exact quality standards.

- Glass Inspection Stations: The workstations are built with fixtures alongside measuring instruments which assist in examining glass components. These controlled stations offer inspectors a place to examine products with full quality control measures thus helping them detect any deviations from technical requirements. The stations play a critical role when producing huge quantities of glass products.

To complement our glass checking fixtures, we also offer a range of

Inspection Fixtures designed for thorough component-level assessments.

Key Features of Glass Checking Fixtures:

We, glass checking fixture manufacturers in India, produce each fixture with unique features to improve its performance and reliability. Some of these features are listed down.

- Precision Measure: To check the glass, the fixtures are used for measuring accurate dimensions. Hence, glass panels and edges and even its corners are found with tolerances for any application like windows, mirrors, or display panels.

- Non-Damaging: Glass checking fixtures are suitable to hold glass panels securely without damaging the glass surface. They feature construction for soft pads, rubberized surfaces, or foam to prevent scratches, cracks, or chips during inspection.

- Adjustable and Modular Design: Many of the glass checking fixtures are adjustable to arrange for various sizes and shapes of glass, thus being flexible for the different types of glass panels. This adjustment makes the fixtures versatile in the inspection of a host of glass items in different industries.

- Easy Handling and Positioning: The fixtures are made for easy placing and positioning of the glass panels, thus cutting down the time and effort needed to prepare for inspections. This becomes important in high-volume manufacturing facilities with efficiency as the core.

- Clear Visibility: Generally, glass checking fixtures have transparent materials or an open structure to allow unimpeded visibility during the inspection. This means the inspector may look closely at the glass surface for any defects, angel dimensions, or imperfections.

Applications of Glass Checking Fixtures:

As glass checking fixture exporters in India, we supply and export top quality fixtures for many applications.

- Automotive: Our glass checking fixtures are used in the automotive sector to check windows, windshields, mirrors, and sunroofs.

- Construction and Architecture: These Glass-checking fixtures are used in the construction industry to scrutinize architectural glass including windows, doors, facades, and skylights.

- Glass Manufacturing: Checking Fixtures are for the glass manufacturers for checking raw glass sheet flatness, thickness, and other critical dimensions before further processing, such as cutting, polishing, or coating.

- Mirror Production: We offer glass checking fixture purposes used in Mirror Production to check the smoothness, thickness, and accuracy of glass.

- Glass Repair Checking Fixture: Checking fixtures verify dimensions and fitment of replacement glass pieces during glass repair and replacement, ensuring the specifications of the original part are satisfied.

Why choose us?

Being the reputed Glass Checking Fixture manufacturers in India, suppliers, and exporters in India, at Unique Circle Engineering Pvt. Ltd, our group of visionary and innovative designers collaborate with our customers to design and create new projects to fulfill accurate specifications. These checking fixtures are produced with the international standards quality and specifications of different industries applications. They are available at customized options to satisfy customers’ needs. Contact us and get the best Glass Checking Fixtures in India!