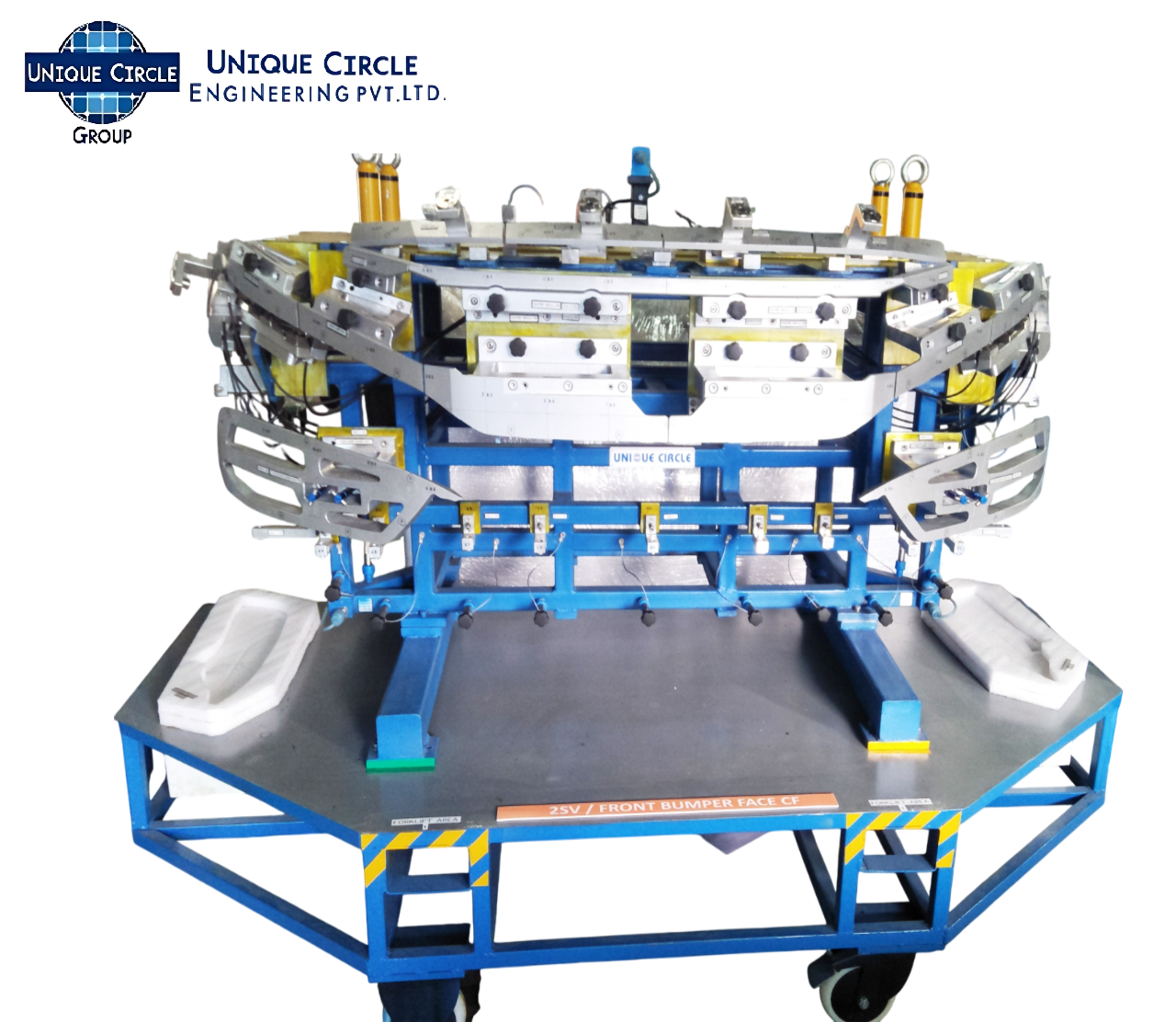

Unique Circle Engineering Pvt. Ltd is the leading Plastic Inspection Fixture Component manufacturers in India, suppliers, and exporters in India. Our offered plastic component checking fixtures are employed primarily for the press, automobile, and sheet metal working machines and tools.

Plastic Inspection Fixture Component Suppliers and Exporters in India

As Plastic inspection Fixture Component Suppliers in India, these are produced and supplied through the use of quality controllers. These precision fixtures are utilized to align and assemble various fix tools, assemblies, and components within reachable distance before welding or any other use. These comply with high standards of quality and are priced affordably. These possess different features, types, and specifications as given below.

Types of Plastic Inspection Fixture Components:

We, Plastic Inspection Fixture Component manufacturers in India, offer various types of it as given below.

- Gauging Surfaces: Technical dimensions receive measuring points from these surfaces which serve as reference points. The surfaces consist of wear-resistant materials to ensure measurement accuracy remains stable throughout their operational life span. Plastic parts need smooth gauging surfaces that should also be non-abrasive to maintain the structural integrity of the parts.

- Clamping Mechanisms: Plastic part evaluation requires clamping mechanisms which maintain the proper position of the parts during testing stages. A consistent yet non-distorting force must be maintained on the part during measurement. The application of quick-release clamps serves to increase production speed.

- Dial Indicators and Gauges: The instruments serve to detect dimensional alterations in addition to spotting any departures from established specifications. The device used in plastic inspection needs enough precision to identify minimal dimensional alterations. The digital indicators both deliver accurate data readings and provide automatic data logging features.

- Base Plates and Frames: The inspection fixture depends on these structural elements to achieve stable rigidity. The devices produce repeatable and accurate measurements. Strong frameworks become essential when measuring large plastic components since they stop the parts from bending.

In addition to precision plastic inspection components, we also manufacture our renowned Master Checker Fixture, which complements component verification with comprehensive fixture accuracy.

Key Features of Plastic Inspection Fixture Component:

As Plastic Inspection Fixture Component Plastic Inspection Fixture Component suppliers in India, these components are designed with different unique features to improve its performance and dependability. Such features are listed down.

- Light Construction: Plastic product inspection fixtures components are lightweight, thus they are easy to handle and manipulate in the inspection process. This feature ensures effective construction and use while preventing operator fatigue and speeding workflow.

- Durability and Strength: Despite lightweight these plastic inspection fixtures are made from durable engineering plastics- ABS, polycarbonate, or nylon. As all these materials provide satisfactory durability and wear resistance, plastic inspection fixtures will withstand repeated use and never lose their functionality.

- Corrosion Resistance: The plastic part Measurement Fixture themselves have excellent internal resistance to corrosion, so they can perfectly be placed in areas where they may come into contact with moisture, chemicals, or other reactive elements. This can increase further the effective life of the fixture.

- Customization: Moulding easily and tailoring to particular parts or applications would be available for plastic inspection fixtures. This flexibility would allow any manufacturer to create a range of fixtures with specific requirements tailored to meet different requirements of plastics.

- Cost-Effective: Much more so than metal fixtures, plastic inspection components are cheaper to manufacture. Low cost equals a cost-effective solution, especially when used in high volume production or areas employing frequent fixture replacements.

Applications of Plastic Inspection Fixture Component:

As Plastic Inspection Fixture Component exporters in India, we supply and export components to many industries for checking the dimensions of plastic materials.

- Plastic Component Quality Control: In industries manufacturing plastic components like the automobile or household consumer goods, they are supported by fixtures during inspection for checking dimensions, shapes, and surface finish of the plastic parts.

- Automotive Industry: Plastic inspection fixtures in automobile manufacturing check the fitting and finishing of the plastic parts in vehicle interiors, such as dashboards, as well as trims and exterior parts.

- Plastic Packing Industry: Plastic inspection fixtures judge packings made from plastics, such as bottles, caps, and containers. These checks purport to ensure the right formation and closure of packaging within the requisite safety and usability specifications.

Why choose us?

Being the recognized Plastic Inspection Fixture Component manufacturers, suppliers and exporters in India, at Unique Circle Engineering Pvt. Ltd, our consistent work and commitment have helped us to attain the satisfaction of our customers and awards. We are always committed in improving the quality of our products, which assist us to remain at par with the developing industry. Contact us and get the best Master Checker Fixture in India!