Unique Circle Engineering Pvt. Ltd is the leading Inspection Fixture manufacturers in India, suppliers, and exporters in India. We offer these Fixture that can accommodate multiple part shapes and sizes. They can be customized and for different components and correct for the specific requirements of a particular industry or application.

Inspection Fixture Suppliers and Exporters in India

Being the best inspection fixture suppliers in India, our Fixture are built from hard materials like steel, aluminum, or strong alloys, which makes them highly capable of bearing the stresses of continued usage without distortion. They will, therefore, offer long reliability and durability under very vigorous conditions of inspection.

About Inspection Fixture

Inspection fixture is employed to clamp parts during checks on dimensions, surface inspection, and other examinations in order to guarantee that the parts have tolerance values and qualify standards. These Fixture are designed to smoothly interface with measurement tools, such as Coordinate Measuring Machines, vision systems, or laser scanners, making them an integral component of modern automated quality measurement systems. They are extremely space-efficient and ergonomically designed- mostly among inspection Fixture-to make handling and operation more efficient. This ensures the Fixture are effective in use and comfortable and safe for many hours of inspection use by operators.

Types of Inspection Fixture:

We, inspection Fixture suppliers in India, offer multiple types of it to suit various applications and their requirements. Some of these types are mentioned below.

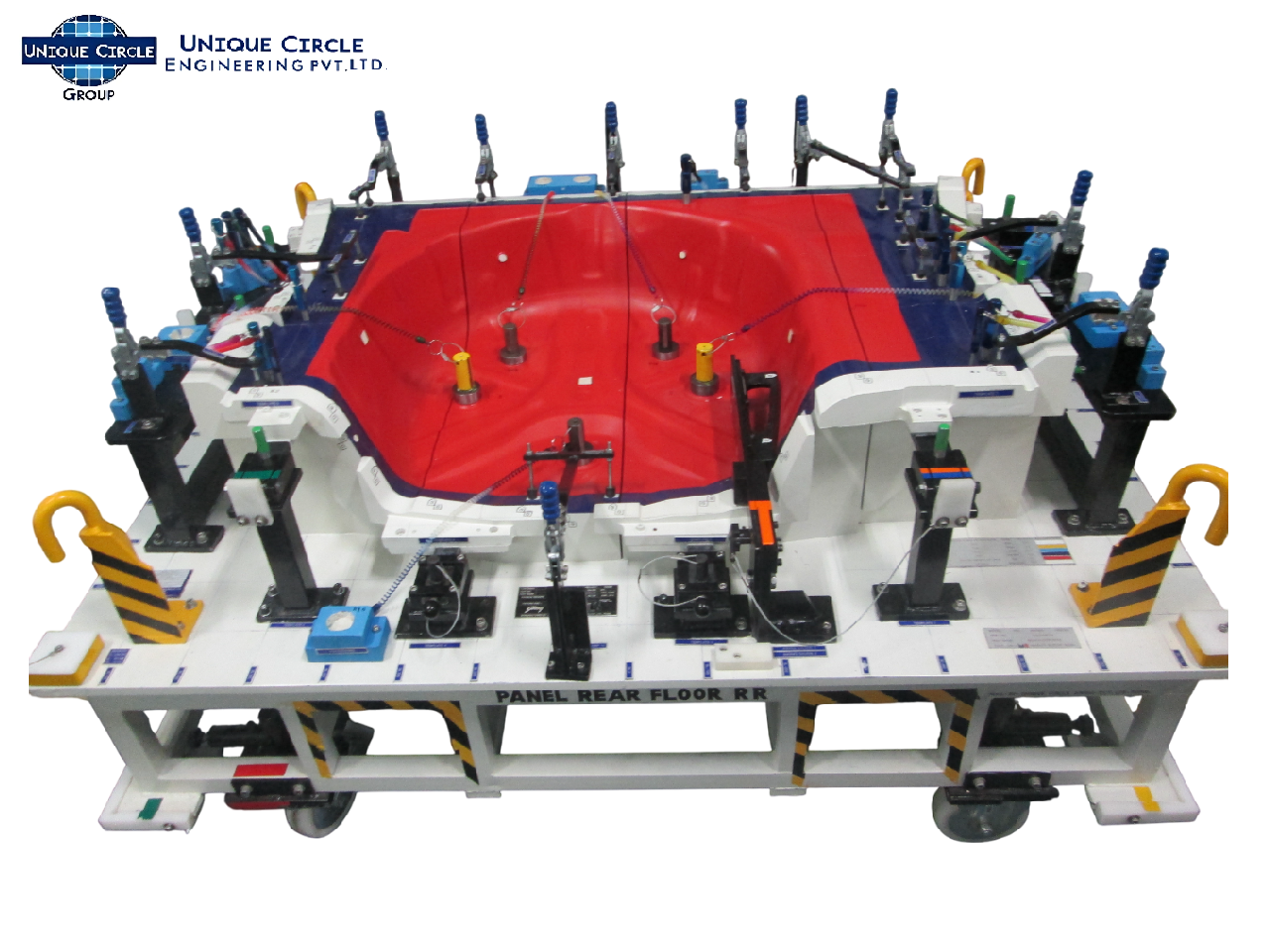

- Automotive Inspection Fixture: These are certainly range from simple to complex Fixture that check dimensional conformity and quality in automotive parts. The primary reason for these Fixture is to check components to very stringent standards for better automotive quality and safety. The second stage of application in the manufacturing processes of automotive products such as body panels and interior parts, among others, requires this Fixture to ensure they get to final production.

- Precision Inspection Fixture: These are Fixture made in the manufacturing process to the intended required high levels of precision accuracy. They are required for use since small dimensional errors could lead to quite major problems. Most industrial application Fixture have advanced measuring methods, along with stable materials, as standard.

- CMM Inspection Fixture: These are the Fixture designed to be used along with the Coordinate Measuring Machines (CMM). The proper location of parts by CMM checking Fixture allows CMM apparatus to conduct precise dimension and shape measurements. When used in such a way, they yield an extremely accurate and very reliable checking function.

- Custom Inspection Fixture: Since mass-produced checking Fixture will never cover all requirements, custom-built Fixture are developed. Such Fixture are designed to fit special measured dimensions of individual components so as to give the maximum support while maintaining very careful checking conditions. The measurement of complexity, as well as irregularly shaped components, indeed deserves special attention.

For detailed dimensional verification, our robust Master Checker Fixtures complement inspection fixtures perfectly by providing high-precision batch-level checks.

Key Features of Inspection Fixture:

We are the best inspection Fixture manufacturers and suppliers in India and design each fixture with a unique feature to improve its performance. Such Features are given as below:

- Precision Alignment: Inspection Fixture provide accurate and repeatable positioning of parts when they are being inspected. They also permit the checking of parts against specifications to allow for accurate and consistent measurements.

- Strong Secure Clamping: These Fixture incorporate extremely strong clamping mechanisms during measurement or test that hold parts in place firmly. Removing the chance of movement, misalignment, or change is very important during inspection because it can cause wrong results.

- Quick Setup and Easy Adjustment: Often these inspection Fixture are made fast-for-assembly and fine-adjustment, which enables the operator to install the fixture in just a few minutes. Thereby, their downtime is reduced to units, resulting in increased overall efficiency in production.

- Non-Damaging Contact: Most inspection Fixture use materials such as rubber, foam, or felt at contact points with parts to prevent any form of scratches or damage, especially during the inspection of finicky or finished parts.

- Modular Design: Some inspection Fixture have modular parts that can be swapped out or rearranged depending on the part being investigated. This provides the versatility to undertake a plethora of inspection tasks within a facility without the requirement of specific Fixture for particular parts.

- High Repeatability: These Fixture assure that the part is returned precisely in the same position for all inspections recorded. This is vital for keeping up dependable and comparable values of the measurements for inspection, particularly in a mass-production environment.

Applications of Inspection Fixture:

As inspection fixture exporters in India, here are some of these applications mentioned.

- Automotive Industry: The checking Fixture would be found in the automotive companies for testing and measurement of engine parts as well as body panels and interior fittings to check their dimensional accuracy.

- Aerospace Industry: Checking Fixture are used in critical applications of aerospace construction like measure turbine blades, fuselage sections, and assemblies of wings.

- Electronics Industry: Of significant importance in this regard are checking Fixture for performing inspections of such things as circuit boards, connectors, and housings of small electronic components.

- Tooling and Die Manufacturing: Checking Fixture are majorly used for inspection in producing tooling and dies in order to ascertain correct and accurate tolerances of the parts as a result of making them.

- Consumer Goods Manufacturing: It will generally be applied on the manufacturing process of consumer goods like appliances, furniture, and toys.

Why choose us?

Being the well-established inspection fixture manufacturers in India, suppliers, and exporters in India, we at Unique Circle Engineering Pvt. Ltd offer the most reliable and customized Fixture to fulfill customers’ requirements. Thus, we ensure that our client will be satisfied with our Fixture. To get the best inspection fixture in India, Contact us or visit our company!