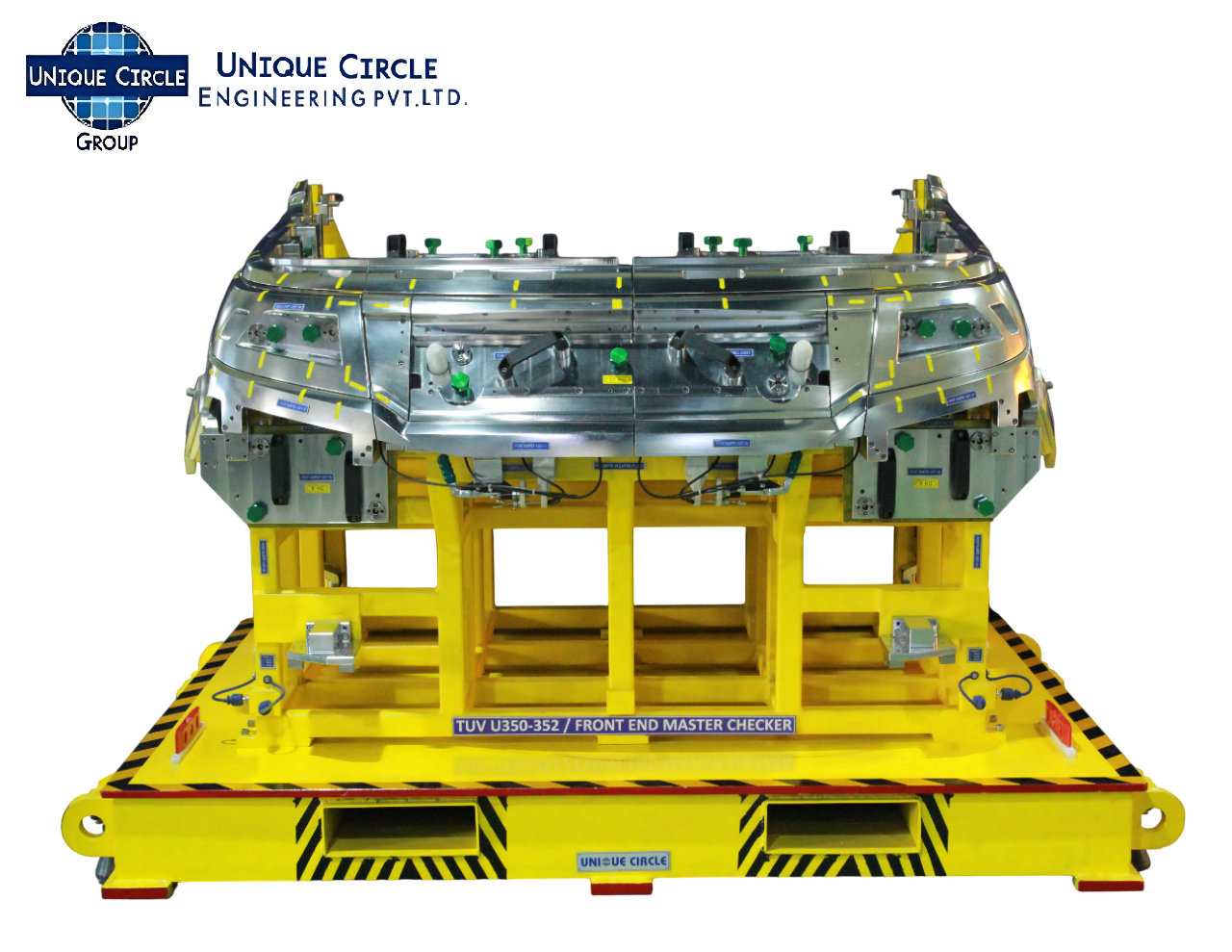

Unique Circle Engineering Pvt. Ltd is the leading Master Checker Fixture manufacturers in India, suppliers, and exporters in India. We design and supply high-quality master checker fixtures for checking master parts or gauges of the machinery. It ensures that these parts would comply with dimensional tolerances and specifications.

Master Checker Fixture Suppliers and Exporters in India

As master checker fixture manufacturers, our company is supported by a spacious state-of-the-art infrastructure, equipped with the latest equipment and machinery. All our amenities and equipment remain in good condition and operate as per newest technology.

About Master Checker Fixture

We offer high-precision master checker fixture which are also measurement and inspection equipment that are crucial in attaining product quality and consistency. They are made up of top-grade components to ensure their quality. The capability to quality check products prior to final production is a critical step towards attaining a reliable system. Our custom designs integrate various elements of inspection equipment specific to the specification in question.

Types of Master Checker Fixture:

We, master checker fixture manufacturers in India, provide different types of it to suit diversified applications. Such types are mentioned as below.

- Master Checking Fixture: The master checking fixture functions as an accurate manufacturing tool for dimensional inspection of manufactured parts. Production parts receive evaluation through reference to this standard. The quality control process depends heavily on these fixtures because they check that all parts match specific design parameters.

- Master Gauge Fixture: A master gauge fixture has the capability to measure and verify exact dimensions and features contained within parts. A gauge fixture evaluates distinct measurements instead of performing checking fixture functions which conduct complete conformity analysis. A combination of calibrated gauges together with indicators provides these fixtures with their accuracy standards.

- Master Inspection Fixture: The quality assessment of manufactured components requires master inspection fixtures to perform complete examinations. The fixture offers a reliable base for inspections that allows authorities to check dimensional precision as well as surface quality and essential specifications. Users can customize these inspection platforms to support multiple measurement techniques that include manual gauging and coordinate measuring machine (CMM) operations and optical examination processes.

- Master Tooling Fixture: During manufacturing operations such as machining and welding and assembly operations the master tooling fixtures operate to securely keep workpieces in exact positions for processing. The fixtures maintain proper placement and orientation of parts to achieve precise operations which are repeatable. The manufacturing process needs these fixtures to ensure precise planning and exact consistency when working on large production volumes.

- Master Calibration Fixture: The calibration and verification of measuring instruments together with other fixtures happen through the usage of master calibration fixtures. These devices function as known precise references which serve to evaluate the compared objects. The use of such fixtures helps extend the measuring instrument's accuracy which produces dependable consistent measurements through time.

In addition to Master Checker Fixtures, we also provide precision Checking Fixtures designed to meet diverse industrial requirements, ensuring accurate and efficient quality checks.

Key Features of Master Checker Fixture:

As master checker fixture suppliers in India, we design and supply each fixture with maintain quality an its unique features which are given as below.

- Precision Measurement: Master checking fixtures are designed for measurements where accurate alignment and dimension verification are required. Such precision is an absolute must for a part to meet demanding design specifications.

- Durability: Master checking fixtures are made from very strong materials such as hardened steel or alloy that assures use in industrial environments almost every day. This very durability ensures that other less-robust designs would lose their accuracy and integrity through excessive handling, while the master checker fixture would still maintain its accuracy.

- Versatility: These fixtures may fit to check and measure vast sizes and types of parts for many different industries. Regardless of whether small or large components are considered, master checker fixtures will afford versatility to application, enhancing their benefits across diverse sectors.

- Easy to Operate: This fixture will allow operators to position parts very fast and accurately, using guides and markers for measurement. With an intuitive design, chances of error are reduced, thus improving the speed of the whole measurement process.

- Repeatability: Reproducing measurements consistently is one of the foremost abilities required. This repeatability assures that every part either produced or measured will fulfill the same rigorous standards, thus reducing variability and enhancing confidence in the quality of the products.

Applications of Master Checker Fixture:

As master checker fixture exporters in India, these are found in many applications to check their gauges or other master parts. Some of these applications are mentioned as below.

- Automotive: In the automotive industry, our master checker fixtures are very critical for checking parts such as chassis, engine components, and body panels. It ensures that every piece complies with the stringent requirements of quality and safety.

- Tool and Die Manufacturing: These master checker fixtures are used in the tool and die industry because there is an emphasis on precision, and the verification of molds, dies, and tooling equipment dimensions are essential for quality-producing components with minimum defects during the mass manufacturing.

- Machinery and Equipment: Master checker fixtures are very valuable with regard to heavy machinery and industrial equipment, as that might ensure that components like gears, shafts, and bearings are machined accurately and aligned. This is also important for the safety and life of machines.

Why Choose Us?

Being the recognized Master Checker Fixture manufacturers, suppliers and exporters in India, at Unique Circle Engineering Pvt. Ltd, our consistent work and commitment have helped us to attain the satisfaction of our customers and awards. We are always committed in improving the quality of our products, which assist us to remain at par with the developing industry. Contact us and get the best Master Checker Fixture in India!